Bolted Joint Analysis

About

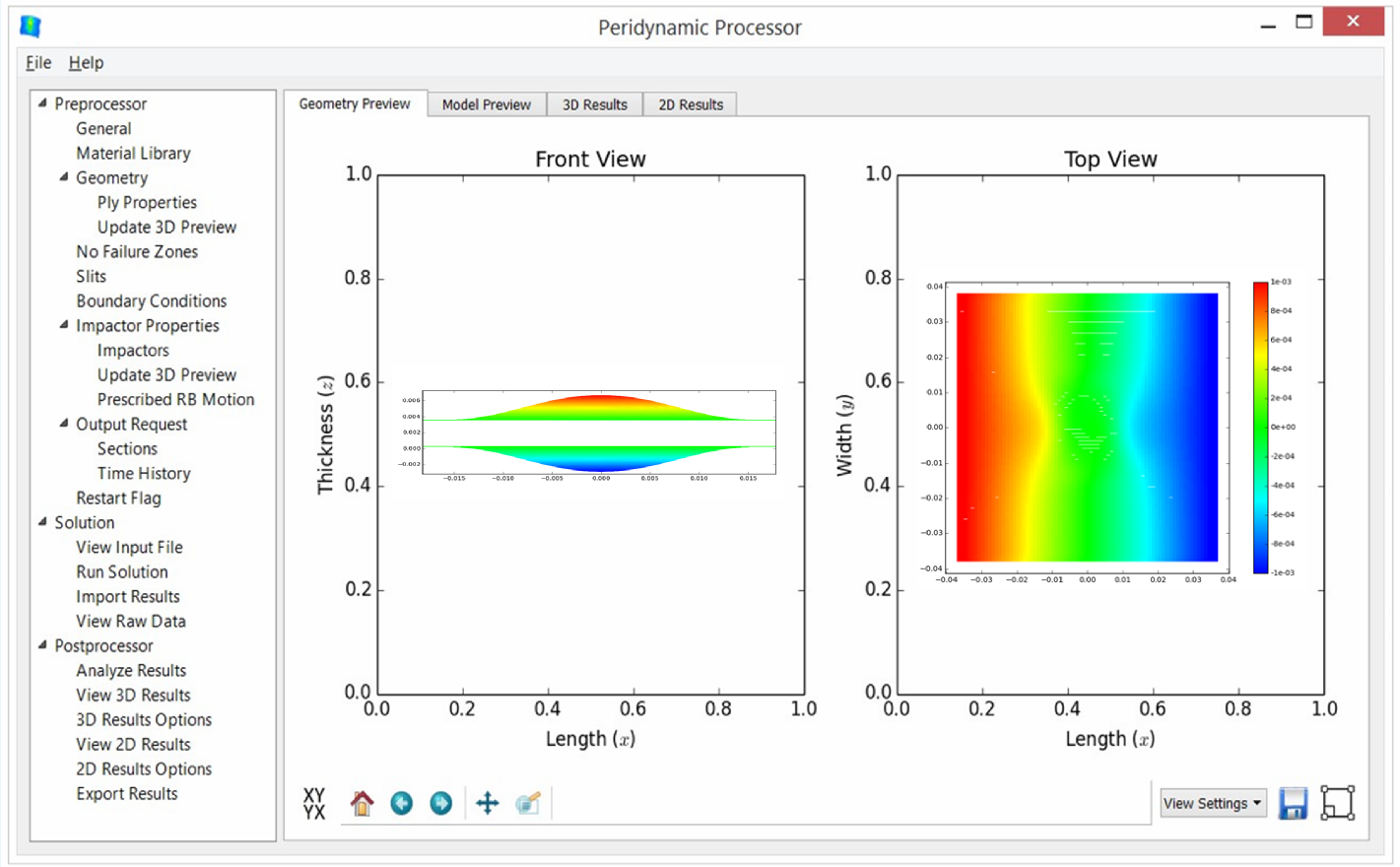

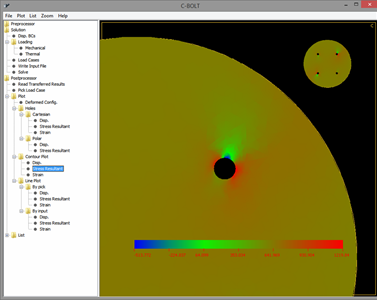

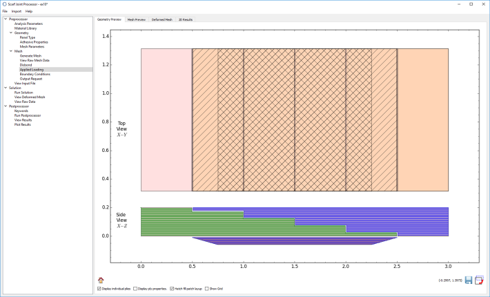

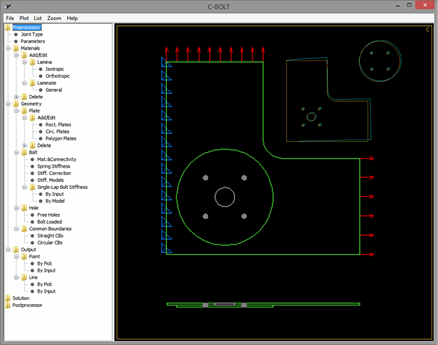

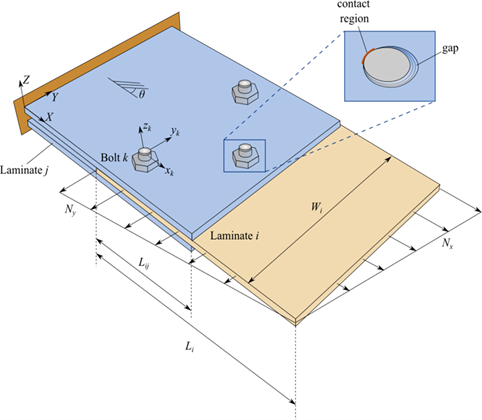

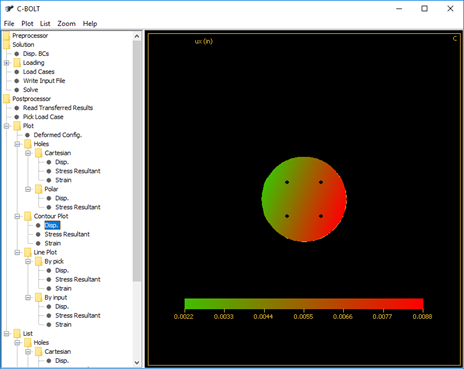

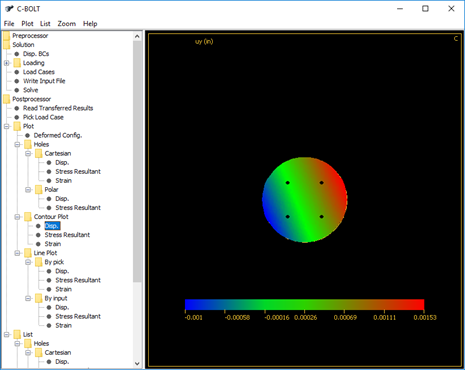

Composite Bolted Joint Analysis Tools (C-BOLT) is a state-of-the-art analysis tool, written in JAVA and FORTRAN, to perform contact analysis of a bolted joint configuration. The configuration can include multiple plates connected via flexible bolts subjected to thermal and mechanical loadings. An iterative solution method is used to determine the contact angles between bolts and plates while considering the initial gaps between them. The plates may have an arbitrary pattern of holes and uniform or linearly varying boundary loads and displacements.

Contact Us

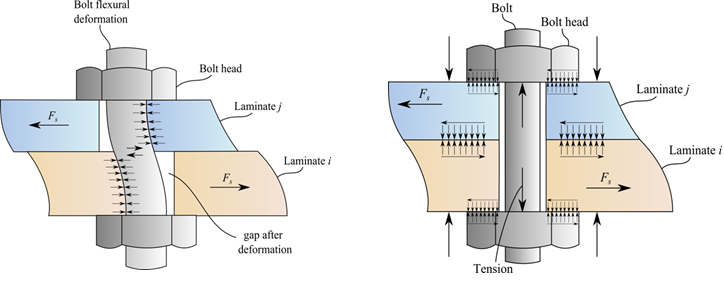

For a stack-up of plates connected by an arbitrary pattern of fasteners, C-BOLT iterates and converges on the contact region between each fastener and plate. The “true” bearing load distribution is therefore obtained, as are stress field interactions between proximate fasteners. Bearing and bypass loads are not subject to the discretization error inherent in plate-spring connector (or beam) finite element analysis. C-BOLT includes the effects of bearing deformation through modeling the fastener and plate contact directly.

Solving a bolted joint configuration containing multiple plates with hundreds of fasteners is extremely difficult and computationally demanding with finite element analysis. The semi-analytical tool C-BOLT is highly efficient and designed for this purpose. It is different from finite element discretization analysis with fasteners modeled as spring connectors or beams without contact to plates. In such finite element fastener models, bearing deformation is implicit in the fastener flexibility (or stiffness) formulas.

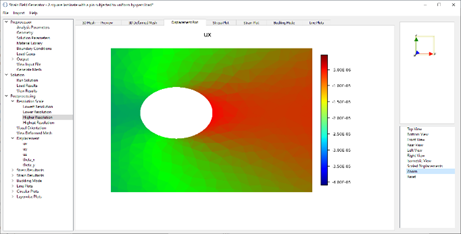

Bolted Joint Analysis is an accurate and fast tool for the simulation and analysis of composite bolted joints under combined thermal and mechanical loads for progressive failure analysis. It is based on a semi-analytical formulation. The interactive user interface allows for graphical previews, reducing iteration time and increasing simulation accuracy. This fully customizable tool enables users to simulate virtually any material and bolted joint configuration.

Features

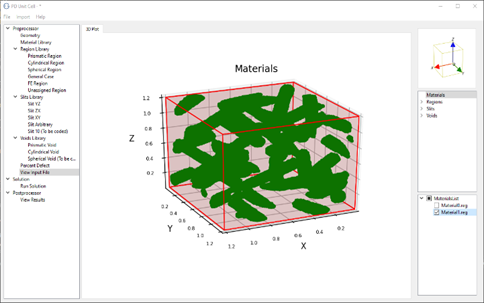

- Complex lap joint designs of multiple dissimilar composite and metal layers with staggered bolts while accounting for the contact phenomenon.

- Presence of friction.

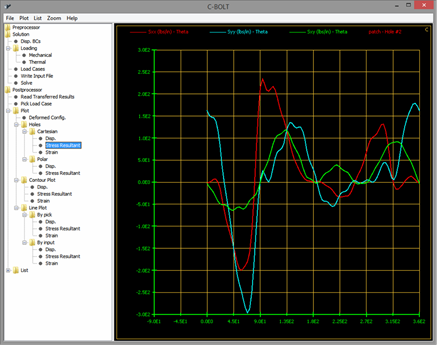

- Interaction among the bolts under complex bearing and by-pass loading for progressive failure analysis.

- Non-linear bearing deformation (bolt-hole elongation).

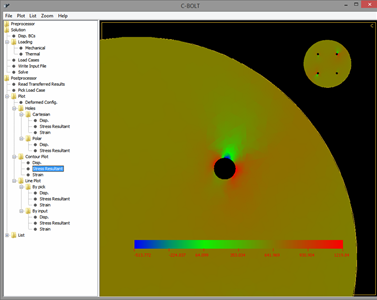

- Complete stress and strain fields.

- Arbitrarily arranged arbitrary number of bolts and composite plates.

- Multiple bolt configurations without need for symmetry assumptions.

Capabilities

- Contact stresses and regions along the bolt-hole interfaces

- Contact stresses and regions between adjacent composite layers

- Bolt and hole deformations

- Stress state in each layer

All Products